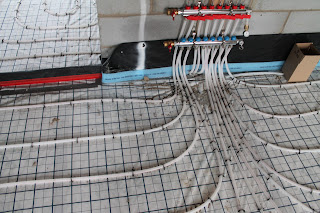

The manifolds will terminate neatly under the stairs, when there are in fact stairs!

The sea of pipes was quite a sight to behold! we have left gaps for some of the architectural fixings like the kitchen island the stairs, toilets. At this point i thought it would be prudent to photograph exactly where all the pipes are so that i cannot have the excuse in the future that i didn't know, when drilling or moving things. This proved one of the most useful exercises when i came to install the stud walls on the ground floor this weekend.

I realised last week that i hadn't introduced the team of builders from Abode, our building contractors. Left to right we have Speedy Tom, French Kenny and Clever Luke. these guys are on site all of the time at the moment with cameos from their colleagues and other trades, they are very tolerant of my inexperience and are very helpful and supportive of my weekend efforts!

Tuesday last week saw the screed team come on site and screed the ground floor, this made a huge difference, it set the ground floor at its proper height and really finished it off from an aesthetic level:-

So last weekend, it was my first attempt at stud partition walls! using Speed line galvanised steel studs, i aimed to get the ground floor studded last weekend and i made it!

We are using double skinned walls, which will be plaster boarded on either side, there will be mineral wool through the middle and this will drastically reduce sound transfer between rooms. It will also create stronger thermal properties as there will be two independent unconnected walls.

This section was the most complicated, here we have what will be the office and on the right a cloakroom and media hub.

its been a busy week on site too! the guys have brought the block work up to form the second floor and by the end of the week most of the blocks will be up to head height of the windows, allowing me to board the second floor on the weekend..

The summit of the tent is being reached and the trusses are on order! talking of the tent, i have made some big underestimates with the tent calculator. Last post showed 45 days tented and 14 saved. the actual number of days tented was 50 and according to the site diary, which the builders keep the actual number of days was 29, due to a mixture of temperature and conditions. this last 2 weeks, the tent has been justified, we wouldn't have got anything done in the last 2 weeks due to the rain so i take great pleasure in correcting and updating the tent calculator as follows:-

No of working days tented (this includes weekends I'm down there too) - 59

No of days saved to weather - 38

No of days done ahead of untended schedule - 7

Chipboad floor onto the top floor this weekend! ill let you know how we get on!

Neil